Press and News

- Details

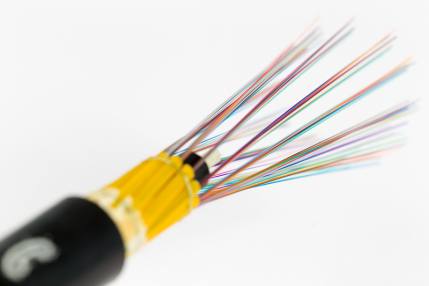

Private sector drives network expansion forward

Companies of the Production Network finance broadband connection from its own resources – partner for the technical implementation is envia Tel

Limbach-Oberfrohna / Gelenau / Hartmannsdorf / Mülsen / Markkleeberg: The Saxon league „The Production Network“accelerates the connection of his seven partner companies to the broadband network. Since 2nd May 2016, the software and IT specialists of DELTA BARTH group as well as the OMEGA Blechbearbeitung AG and the Limbacher Oberflächenveredelung GmbH already have access to internet with maximum speed. The financing handles the network completely from its own resources. Partner for the technical implementation is the telecommunications provider and network operator envia TEL.

All partners of the Production Network will be supplied step by step with the powerful fibre-optic connection. In July 2016, the connection of the Antares GmbH in Hartmannsdorf and the AMS Technology GmbH in the industrial part south in Limbach-Oberfrohna will be implemented. Schwalbe Metallbau GmbH based in Mülsen near Zwickau as well as the GEMAG Gelenauer Maschinenbau AG will be connected to the broadband network of envia TEL until September 2016.

- Details

News from “The Production Network”

How Six Men Got On in the whole world - seven come much further: “The Production Network” travels with his new business partner and the patented laser protection system "A-Protection" to the Hannover Fair

Smooth implementation - in perfect synergy! According to this motto, “The Production Network” realizes since 2009 major projects in the fields of agricultural engineering, mechanical engineering, rail and special vehicle construction as well as medical technology and apparatus construction -worldwide. Saxon league will present his new and therefore seventh partner at this year's Hannover Fair: Schwalbe Metallbau GmbH.

- Details

The Production Network is growing beyond itself

Saxon league will attend with his new network partner as well as the patented laser protection system the Hannover Fair

Limbach-Oberfrohna, Gelenau, Hartmannsdorf, Mülsen:

„The Production Network“ will present his new partner of the saxon league at this year’s Hannover Fair from 25th until 29th of April: Schwalbe Metallbau GmbH. On the network stand F24/2, (6) in Hall 4, they will also present market innovations such as the patented laser protection system “A-Protection“ as well as longstanding success stories of the from now on seven partner companies. One example: the delivery of the 500th hull machine, manufactured in real teamwork.

Since September 2015, the company Schwalbe Metallbau GmbH from Mülsen acts as new, powerful partner in the Production Network. With the strength of 80 employees, the company stands for excellence in the field of steel construction and engineering. They cut, bend, weld, paint and mount up to 10 tons workpiece weight in the area of serial production and even more then 10 tons in the area of individual production. “We are able to extend the portfolio of the Production Network in the fields of sheet metal processing and steelwork design and we can develop further the output capacity of the network in the field of engineering and plant construction at the same time”, explains Marko Seidler, CEO of Schwalbe Metallbau GmbH.

Market innovation: laser protection system “A-Protection“ reaches series production readiness

The modular laser protection system “A –Protection” is an example of inventiveness and real teamwork „Made in Saxony“ which will be presented in the serial production design at the Hannover Fair. The laser protection wall from high quality materials and durable construction design ensures maximum protection against hazardous radiation. By stringing together, the individual wall elements can be combined to create a powerful laser protection cabin. The cabin encapsulates the working space and therefore ensures a reliable passive protection with modern 3D laser cutting and laser welding unit. Even highly brilliant laser with a power up to 10 kW cannot penetrate into this laser protection. Strayed laser beams caused by scattering or direct reflection can therefore pose no risk to the health of the operating personal. The highlight of this solution is that the wall will not be damaged and the machine can always continue to work unhindered.

The laser protection system „A-Protection“is a patented innovation of the network partner ANTARES GmbH. “Only with the background of the Production Network, we are able to serve numerous potential partners mainly from the area automotive smoothly and in time”, explains Jörg Bergelt, CEO of the ANTARES GmbH. Each step in the production of the laser protection system is implemented within the Production Network – from the design through production and coating, up to the assembly of the plants.

Anniversary: 500th hull machine leaves the factory halls of GEMAG

The following anniversary shows how successfully the Production Network implements their major projects in the sectors of agricultural engineering, mechanical engineering, rail vehicle construction, special vehicle manufacturing as well as medical technology and apparatus construction: In January 2016 the 500th hull machine left the factory halls of the Gelenauer Maschinenbau AG. “500 machines of this complex type in barely five years are a masterpiece because the serial nature in the sector of German mechanical engineering is declining”, said Hans-Peter Weise, executive board of GEMAG. The further expansion of the business segment mechanical engineering components – especially machinery bodies, hull or base machine and tool magazines – is only realizable within the strong community of the Production Network. Know-how and capacity for the therefore required steel structures, sheet metal parts, sheet covering and complete enclosures, coatings according to customer requirements as well as stainless steel components will be provided efficiently and in time by the network partners.

Stops including spaces: 4128

pictures: Wolfgang Schmidt

- Details

Achieve more together

Companies of Limbach-Oberfrohna contribute for the good purpose

Limbach-Oberfrohna: Five companies of Limbach-Oberfrohna also demonstrate animal commitment and sport spirit for kids this year and support different local clubs with 3.000 € in total under the motto „Achieve more together“. After the call of the contribution unit AMS Technology GmbH, DELTA BARTH Systemhaus GmbH, DELTA proveris AG, Limbacher Oberflächenveredelung GmbH and OMEGA Blechbearbeitung AG to present concrete project plans three of twelve transmittals had been selected.

To enlarge and to develop age-based offers for the spare time and learning in Limbach-Oberfrohna is most important for the Managing Boards and Directors of the companies. „Finally, we employ a large amount of employees from Limbach-Oberfrohna and surroundings. It is important for us that manifold possibilities are also offered for kids in our town to create an active spare time. But some plans can not be executed by oneself“, Andreas Quellmalz explains, Managing Board of the OMEGA Blechbearbeitung AG, the selection of the clubs which can be happy about the contribution this year. The enlargement of the zoo school from the Tierparkförderverein e.V. as well as the projects „Sport for preschool kids“ of the TuS Falke Rußdorf e.V. and „Bambini-Badminton“ of the Sportgemeinschaft Bräunsdorf e.V. are subsidised by the contribution unit with each 1.000 Euro. It has already been a tradition for the companies of Limbach-Oberfrohna to support regional clubs and social institutions together by the campaign „Give instead of gifts“ instead of sending gifts to business partners and customers.

Signs incl. blanks: 1.727

- Details

Donate, Contribute and Inspire

Companies of Limbach-Oberfrohna plan new contribution campaign

Limbach-Oberfrohna. Under the motto „Achieve more together“, the companies from Limbach-Oberfrohna AMS Technology GmbH, DELTA BARTH Systemhaus GmbH, DELTA proveris AG, Limbacher Oberflächenveredelung GmbH, OMEGA Blechbearbeitung AG contribute each year 3.000 € for a good purpose and show commitment for their region.

Since a longer time, the companies have already been resigned to send gifts to customers or business partners. „We dare to support regional associations and social institutions which make people happy“, Annett Barth, managing director of the DELTA BARTH Systemhaus GmbH, explains.

This year, all institutions shall get the chance to present their concrete projects. „For sure, there are some institutions which do not have any awareness in the publicity, but whose work provides an important social part“, Uwe Jentsch, managing director of the LOV Limbacher Oberflächenveredelung GmbH, describes the background of the current contribution campaign.

A concept shall be stated on maximum three A4-pages with the presentation of the institution and/or the association, a description of the project content which shall be realised with the contribution, the target group as well as the time period of the implementation.

Until the 18th of September 2015, social projects can be sent under the motto „Contribution 2015“ per postal way to the DELTA BARTH Systemhaus GmbH, Ludwig-Richter-Straße 3, 09212 Limbach-Oberfrohna or E-mail presse@delta-barth.de. If you have any questions please ask Kathleen Donath under phone 03722/71700.

- Details

Raising the Curtain for Snow White and the Seven Dwarves

Limbach-Oberfrohna Companies Sponsor Special Excursion for Nurseries and Primary Schools

Limbach-Oberfrohna. "Mirror, mirror on the wall ..." On September 17 and 18, 2014, nursery and primary school children from Limbach-Oberfrohna were invited to come to the country behind the seven mountains where the seven dwarves live. 795 young attendees and their 92 adult companions did not want to miss this great day of theatre. The performance of the play "Snow White and the Seven Dwarves" was sponsored by local companies AMS Technology GmbH, Delta Barth Systemhaus GmbH, Delta proveris AG, Limbacher Oberflächenbearbeitung and Omega Blechbearbeitung AG.

Limbach-Oberfrohna. "Mirror, mirror on the wall ..." On September 17 and 18, 2014, nursery and primary school children from Limbach-Oberfrohna were invited to come to the country behind the seven mountains where the seven dwarves live. 795 young attendees and their 92 adult companions did not want to miss this great day of theatre. The performance of the play "Snow White and the Seven Dwarves" was sponsored by local companies AMS Technology GmbH, Delta Barth Systemhaus GmbH, Delta proveris AG, Limbacher Oberflächenbearbeitung and Omega Blechbearbeitung AG.

The talented young actors of the children and youth theatre group BURATTINO from Stollberg played in the Limbach-Oberfrohna city hall. There, they gave a total of three shows in front of an audience of excited three- to eight-year-olds.

A complete success. Ute Hecht, director of the day-care centre "Bärenstark" on Heinrichstrasse agrees: "We were very happy about this great idea of organizing this event for the children. Especially, since our own budget is so tight. We came here with our preschoolers and even our youngest who are only three years old. This theatre day was a highlight for all of us. We, the children's institutions of Bona Vita, as well as the parents and especially the children are thrilled to be here."

The event was meant to be an early Holiday gift for nursery and primary school children. Instead of giving gifts to their customers and business partners for the holidays, each year the companies give to social institutions in Limbach-Oberfrohna. "This way, we want to support the work of the various institutions in our city and most of all, give happiness," says Annett Barth, Director of Delta Barth Systemhaus GmbH. The timing of the shows in autumn was mostly for practical reasons: "The calendars of schools and nurseries are already packed with events during the Holiday season," explains Andreas Quellmalz, member of the board of Omega Blechbearbeitung GmbH. "Therefore, we wanted to create an additional highlight in autumn."

- Details

Saxony's Minister for Europe, Dr Jürgen Martens visits Omega Blechbearbeitung AG

Limbach-Oberfrohna. On Tuesday, July 22, 2014, Saxony's minister for Europe Dr Jürgen Martens visited the Omega Blechbearbeitung AG in Limbach-Oberfrohna. Andreas Barth, member of the board of Omega Blechbearbeitung AG, explained to him the opportunities of sheet metal forming and surface treatment.

Omega Blechbearbeitung AG is a specialist for the engineering, production and assembly of sheet metal assemblies made of steel, stainless steel and aluminium. Among other things, it produces machine claddings, facilities for the medical sector, switch cabinets, and manufacture for agricultural engineering. The majority of the products is exported - either within Europe or worldwide. During the factory tour, Dr Jürgen Martens convinced himself of the excellent production equipment, the variety of the products as well as the first-rate logistics.

All these factors mean that the Omega Blechbearbeitung one of the best medium-sized companies in Saxony. "The increaing percentage of exports from medium-sized companies in Saxony is an encouraging sign. This creates highly qualified jobs that make Saxony one of the most competitive regions in the European Union. The Saxon state government will continue to improve the regulatory framework for such medium-sized companies," says Dr Jürgen Martens.

The two also discussed topics that concern the work of medium-sized companies that need to be addressed by politics, such as reforms to further reduce red tape.

- Details

Nurseries and Primary Schools Invited to Theatre Performance

Limbach-Oberfrohna Companies Sponsor Special Excursion

Limbach-Oberfrohna. "Mirror, mirror on the wall ..." In September 2014, nursery and primary school children from Limbach-Oberfrohna are invited to come to the country behind the seven mountains where the seven dwarves live. Adventure, real friendship, true love and more await beautiful Snow White on the stage of the Limbach-Oberfrohna city hall. The performance of the play is sponsored by local companies AMS Technology GmbH, Delta Barth Systemhaus GmbH, Delta proveris AG, Limbacher Oberflächenbearbeitung and Omega Blechbearbeitung AG.

The Limbach-Oberfrohna city hall will see the children and youth theatre group BURATTINO from Stollberg perform. The talented young actors will stage the popular fairytale by the borthers Grimm for an audience between three and eight years of age.

The event is meant to be an early Holiday gift for nursery and primary school children. Instead of giving gifts to their customers and business partners for the holidays, each year the companies give to social institutions in Limbach-Oberfrohna. "This way, we want to support the work of the various institutions in our city and most of all, give happiness," says Annett Barth, Director of Delta Barth Systemhaus GmbH. The timing of the shows in autumn is mostly for practical reasons: "The calendars of schools and nurseries are already packed with events during the Holiday season," explains Andreas Quellmalz, member of the board of Omega Blechbearbeitung GmbH. "Therefore, we wanted to create an additional highlight in autumn."

Until June 27, 2014, interested nurseries and primary schools from Limbach-Oberfrohna can register for the event. Tickets are only available while stock lasts.

- Details

The Production Network expands production capacities

Strong production with service ambition is present on SIT Chemnitz

Limbach-Oberfrohna/Gelenau/Hartmannsdorf: The Production Network shows highligths even in the fifth year of the cooperation. The six partner companies from Saxony stand for performance power with service ambition. The Network is present on the SIT, the Saxon industry and technology trade from the 14. until 16. Mai 2014, in hall 1 at the booth F4. High-quality product news, mobile concepts as interface between business software and production as well as innovative production processes are represented.

One network, six specialists with organisation talent: The companies OMEGA Blechbearbeitung AG, GEMAG Gelenauer Maschinenbau AG, AMS Technology GmbH, LOV Limbacher Oberflächenveredlung GmbH, ANTARES - industrielles Engineering - GmbH as well as DELTA BARTH Systemhaus GmbH realise together industrial large projects. From the construction until the implementation of the plants – all working steps are reproduced within the Production Network. That means for the customers: one contact partner for the whole project, fast and exact order procedure as well as technology on top level.

At the IT-user forum which takes place during the SIT the Production Network presents two papers which show in details the purpose of business software for the simplification of the daily working processes as well as an energy-efficient handling with company resources:

- 15. Mai 2014, 4:00 pm

Sustainability pays – energy efficiency by software support

Consultants: Martin Lippmann (DELTA BARTH), Jörg Seiche (LOV) - 16. Mai 2014, 2:30 pm

Usability – About the meaning of the usability of business software at the example of ERP-systems

Consultants: Anett Klein (DELTA BARTH), Nina Bär (competence centre Usability for the middle class, TU Chemnitz)

The Production Network started convincingly to its anniversary year. The six partner companies offer many technological further developments and new production possibilities at the fifth anniversary. So, the AMS Technology GmbH installed a large clean room in which apparatuses and plants are produced under high purity requirements for the pharmaceutical and cosmetic industry. The grindery/surface technology of the company stands for the surface quality on top level which had been expanded to ca. 600 qm due to the positive order situation.

The GEMAG Gelenauer Maschinenbau AG also offers a lot of space for innovative ideas with its new 2,400 qm large assembly and stock hall. The network partner is also characterised by a sophisticated quality feature for the German tool machine building due to the new workplaces with anti-glare lighting for the hand-scraping of highly precise pieces. Furthermore, the company produces due to the highly modern CNC-large processing centre UNIPORT 7000 KW in the premium scope of the XXL-processing. The GEMAG invested about 25 Mio Euro at the location Gelenau in the last eleven years and can show today one of the most modern production locations in Europe in the scope of the large processing for the small and middle series production.

The specialist for machine housings, ANTARES GmbH, represents its new product series of laser protection cabins for lasers of high brilliance as they are used for example at modern 3D-laser cutting and welding plants. The construction and production of compact welding cells for the vehicle industry with ready-for-connection device and robot integration as well as modular transfer stations for transfer streets are further technical highlights of this network partner.

The Limbacher Oberflächenveredlung GmbH represents as specialist for high-class, scratch- and weather-resistant surface coatings in the inner and outdoor area. The contract coater, well known throughout Germany, had been awarded for its sustainable company concept – based on the highly modern and with it resource-economical powder and wet coating plant – with the "besser lackieren Green Award 2013". Furthermore, the LOV could receive the Saxon business energy pass as a further appreciation of the energy-political services from the Saxony minister of economy on the 04. April 2014.

In order to organise the processes within the company union more efficient and without media discontinuity all networkers work with the ERP-software DELECO® from the company DELTA BARTH Systemhaus GmbH. The software specialist goes for simple and traceable processes and presents two new Apps at the SIT that can be used for the registration of inventory data and stock transfers directly via smartphone or tablet-PC. Furthermore, DELTA BARTH presents its current software for the maintenance management, DELECO® IMS. The new version 6.31 which is available since April of this year stands for the continuous documentation, optimised fast accesses to processes that belong together thematically and logical usability at all levels.

The production network provides complete solutions with service ambition. The six companies realise their mutual projects for the general machine building, the optical as well as food processing industry and the tool machine building for example. The concept of the network functions worldwide: The plants from Saxony have already been in use in many countries of Europe, the USA, Japan as well as in the Arabic Area. This trend also brings out the balance of the partner OMEGA Blechbearbeitung AG. The high-quality products of the company are required worldwide much stronger. The company could continue its increased international direction as system supplier with a strong diversified customer base in the most different scopes. In 2013, an export part of about 31 Prozent had been reached. Herewith, the high-power machine park of the OMEGA also plays a key role. In the year 2013, this had been added amongst others by a program-controlled welding robot of the company Cloos which has two welding stations for simultaneous setting-up and processes cycles as well as by a blasting cabin for the blast cleaning of single parts and boards before the surface treatment.